The Best Strategy To Use For Welders In Leeds

Table of ContentsAbout Welders In LeedsWhat Does Welders In Leeds Do?6 Simple Techniques For Welders In LeedsAn Unbiased View of Welders In LeedsFacts About Welders In Leeds RevealedNot known Incorrect Statements About Welders In Leeds

Stick welding) MIG Welding TIG Welding If you're a novice then picking the incorrect welding procedure can indicate the distinction in between you enjoying this as a pastime, or being simply plain disappointed. How to bond can be really time consuming, and hard if not done right. Let's briefly speak about each procedure, and after that I'll expose the simplest procedure for you to start with.

The majority of times it's acetylene mixed with oxygen, however often it's gas combined with oxygen. In either case, a fuel gas is always blended with oxygen to achieve the heat required to melt steel. The temperature level of an oxy acetylene flame burns at about 6,632. That's freaking hot! The flame is used to heat the metal until a molten weld puddle is formed.

A filler rod is merely a rod of metal that is dipped into the weld puddle that ends up being the weld bead. An oxy-fuel setup like this is really flexible. You can not only weld steel, aluminum, copper, stainless steel, and more You can also use it as a cutting torch, to bend metal, and even to do metal brazing (where you sign up with 2 pieces of metal together with a bronze filler metal).

Getting My Welders In Leeds To Work

While discovering this process first (as they do in lots of welding schools) will allow you to learn how to control the molten weld puddle, it isn't needed. This welding process fell out of favor with the advent of electrical energy, but it was commonly utilized in the mid 1800's all the way approximately the turn of the 20th Century.

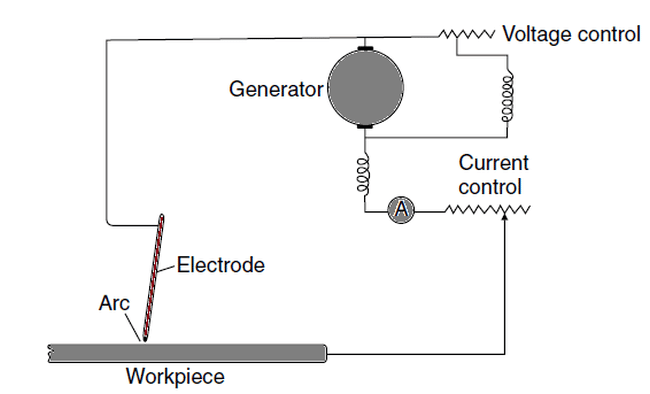

It was the first electrical welding process to be developed, and it's still extremely commonly utilized today. The image of a stick welder is most likely what you think about today when you envision someone welding. There's the long electrode (stick) connected to a stinger that runs an electric current through the electrode, triggering a short circuit at the workpiece.

Welders In Leeds Can Be Fun For Anyone

See, you can purchase stick electrodes in any metal you want to bond. So, if you have an aluminum boat you wish to weld on, just buy some aluminum electrodes. Exact same for moderate steel, stainless, and so on. Stick welding is understood for its ability to get deep penetration in metal. So, it's frequently utilized when welding in shipyards, boilers, and other fields where the inmost weld penetration is required.

This is why they're called consumables. And when you take a look at a finished weld, the weld bead you see is that electrode actually burned down to present a weld bead. Nevertheless, this does suggest that you need to stop quite typically to discard your old electrode, and include a brand-new one.

Another factor it's called stick welding is because your electrode often sticks to the metal when starting your arc. It can be annoying to state the least. It's not unusual to invest a minimum of the very first thirty minutes to an hour simply finding out how to get a scratch start going.

The Best Guide To Welders In Leeds

This finishing is an absolute essential, and without it your welds would be really weak. That's because in order for a weld to be solid all the way through, you need to keep the atmospheric gases away from the puddle. Otherwise, gases like nitrogen and oxygen will "infect" the weld, causing small pinholes.

This helps maintain a correct weld. go to this site If you're a novice to welding, MIG welding lacks a doubt the process that will get you up and running rapidly and smoothly. With MIG (aka. GMAW Welding) the electrode begins a roll of constantly fed wire, rather than a "stick". And with MIG you have a handheld weapon.

It's basically an endless supply of welding wire because you don't need to change out the roll of wire very frequently. At least not for the house enthusiast or weekend warrior. You have 2 options with a MIG welder. You can pick to weld with either flux core wire, or with strong wire.

The Main Principles Of Welders In Leeds

Opposite to that of stick welding. However if you're utilizing strong wire then you need to use a shielding gas. Typically you 'd use C25 gas which is a read this mix of 25% co2 and 75% Argon. This shielding gas does the same thing as flux. It purges the weld location of any oxygen or nitrogen that might infect the weld.

I recommend buying one that has the ability to use it with gas and with flux core. Some just use a flux core alternative. You'll be disappointed if you go this route - welders in leeds. You can weld practically any metal with a MIG welder. Aluminum site here welding does need that you utilize an aluminum spindle weapon.

Tuning your MIG welder (ie. setting the wire speed and voltage properly) will make or break your welds. Lots of newbies end up welds that appear like bird poop merely because they haven't got this part right. But, once it's setup and tuned you just pull the trigger and you're welding.

Some Known Questions About Welders In Leeds.

To successfully find out to bond with a MIG welder you need to master not only a flat position weld, however likewise, horizontal welds, vertical welds, and overhead welds. On top of that, you need to master the welding joints. Don't start a task before doing this. You'll require to know how to bond fillet joints, lap joints, corner joints, t joints, and more.